Smith Springs Truck Suspension

At Smith Springs, we are the leading experts who specialize and understand everything there is to know about Spring and Suspension systems.

All front and rear suspension systems have 2 primary functions:

- 1.) suspension maintains the weight of a truck and its cargo

- 2.) suspension absorbs the bumps and defects on the road

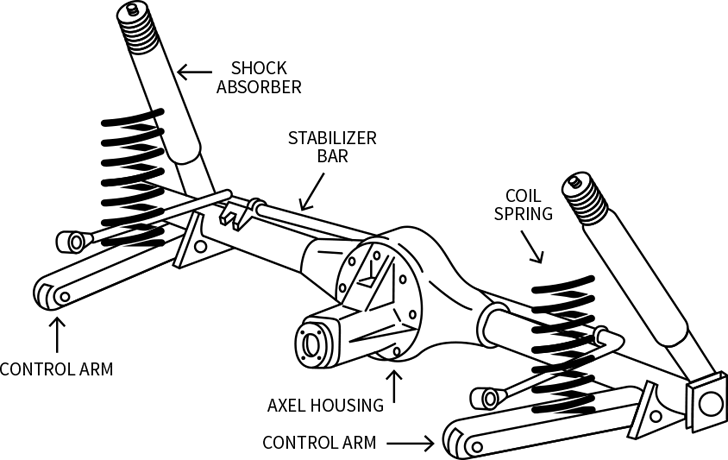

Together the front and rear suspensions work very hard to ensure the stability of the cargo and truck. The strength of suspension comes from primarily its springs in which it is seated. The springs suspend the frame of the truck during different driving conditions including acceleration, braking, sharp turns, terrain changes and differences in weight distribution. Without these systems in place to compensate the conditions of the road, trucks would be unstable and overturn.

There are several types of suspension systems that trucks have nowadays and we know how they all work and how to repair/replace them quicker than our competitors. With over 20 years of experience, we can boast that we are a leading authority of all types of spring and suspension systems in the Midwest.